Checking Out Laser Galvo and Its Influence On Modern Manufacturing Modern Technology

Checking Out Laser Galvo and Its Influence On Modern Manufacturing Modern Technology

Blog Article

Discovering the Benefits of Digital Galvo Scanners for Boosted Performance

The combination of digital galvo scanners is changing efficiency metrics in laser handling applications, defined by significant innovations in accuracy and operational speed. What ramifications do these improvements hold for the future of laser modern technology and manufacturing methods?

Improved Precision and Accuracy

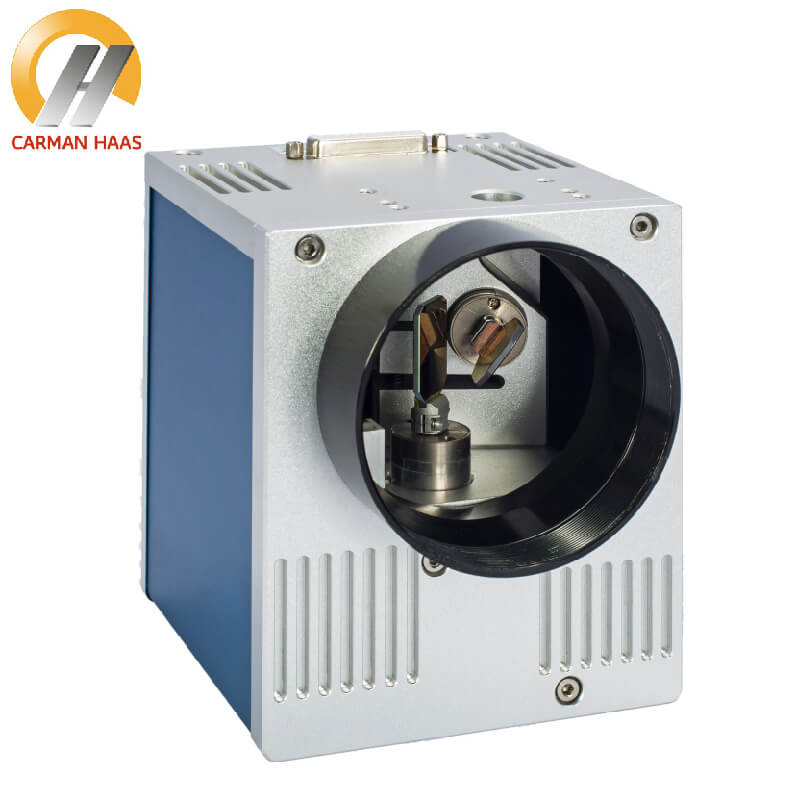

Digital galvo scanners have actually changed the area of laser processing by enhancing precision and accuracy in various applications. These advanced systems utilize galvanometer-driven mirrors to guide laser beam of lights with exceptional control, dramatically minimizing the margin of mistake connected with standard laser systems. This enhanced precision is especially valuable in sectors such as production, clinical device fabrication, and electronic devices, where detailed styles and limited resistances are crucial.

The ability to accomplish specific laser placing enables for finer detailing and enhanced quality in engraving, reducing, and noting procedures. Digital galvo scanners can implement complicated patterns with very little deviation, making certain that completion products meet rigid specifications. In addition, the real-time comments systems integrated within these systems facilitate constant adjustments, additionally enhancing the total accuracy of laser procedures.

Moreover, the high-speed action of galvo scanners makes it possible for regular performance throughout various products and densities, lowering the risk of problems. As a result, producers can attain a lot more trusted outcomes, bring about increased consumer fulfillment and minimized waste. In summary, the accuracy and accuracy supplied by electronic galvo scanners are pivotal in advancing laser handling innovations, making them vital devices across several markets.

Enhanced Speed of Procedure

Frequently, the assimilation of galvo scanners right into laser processing systems results in a considerable rise in operational speed. This improvement is primarily credited to the scanners' capacity to rapidly reposition the laser beam with phenomenal dexterity and accuracy. Unlike standard stepper electric motors, which require time to accelerate and slow down, galvo scanners utilize mirror-based systems that assist in near-instantaneous movement. This capacity enables for faster processing times, ultimately boosting overall throughput in making settings.

Furthermore, the high-speed operation of galvo scanners allows constant processing, lessening idle time and raising efficiency. The scanners can manage complex patterns and high-density layouts without giving up speed or top quality, making them excellent for applications such as engraving, cutting, and noting.

Versatility Throughout Applications

Galvo scanners are increasingly acknowledged for their convenience across a variety of site here applications in laser processing. These innovative gadgets enable precise laser beam of light adjustment, making them appropriate for varied jobs such as inscription, cutting, and Check This Out noting on numerous materials, consisting of metals, plastics, and ceramics - Laser Galvo. The capacity to rapidly reposition the laser light beam enables intricate designs and patterns, enhancing creative opportunities in industries ranging from producing to art

In enhancement to traditional applications, electronic galvo scanners are likewise utilized in innovative areas such as medical gadget production, where precision is extremely important. Their ability to operate at broadband while preserving precision makes them excellent for processes like laser welding and ablation. In addition, their flexibility to different laser wavelengths and power settings ensures compatibility with various products, broadening their application range.

Furthermore, the combination of galvo scanners with automated systems improves their performance, enabling seamless operation in robot and manufacturing line environments. This versatility not only maximizes operations however also sustains personalized remedies tailored to details industry needs. Ultimately, the adaptability of digital galvo scanners positions them as beneficial possessions in modern laser handling innovations.

Cost-Effectiveness and Effectiveness

Just how do cost-effectiveness and performance contribute in the fostering of laser modern technologies? The enhancing need for exact and fast handling in numerous industries has actually militarized the integration of electronic galvo scanners, which use both cost advantages and functional effectiveness. These scanners streamline laser applications, minimizing product waste and decreasing operational prices connected with traditional techniques.

Digital galvo scanners improve efficiency by enabling faster handling rates, which equates to much shorter manufacturing cycles. This efficiency not only improves throughput however also permits business to fulfill limited deadlines without compromising quality. Furthermore, the decrease in energy consumption during laser operations adds to reduce utility prices, even more boosting overall cost-effectiveness.

In addition, the long life and integrity of galvo scanners reduce maintenance costs, as pop over here they need much less regular maintenance contrasted to various other laser systems. As businesses make every effort to stay competitive, the adoption of cost-efficient options like electronic galvo scanners is vital.

Improved Customer Experience

The assimilation of electronic galvo scanners dramatically enhances the user experience in laser applications, supplying drivers with instinctive controls and real-time feedback. This innovative modern technology enables for specific manipulation of laser beams, enabling individuals to accomplish detailed designs with very little initiative (Galvo Head). The user-friendly user interface often includes visual depictions of laser paths, simplifying the shows process and decreasing the learning contour for new drivers

Furthermore, electronic galvo scanners provide fast response times, which improves process efficiency. Operators can make modifications on the fly, permitting for immediate aesthetic feedback throughout the laser processing. This responsiveness not just enhances productivity yet likewise promotes an extra appealing and interactive working setting.

In addition, the capability to quickly incorporate with existing software application enhances compatibility and customer convenience. Numerous digital galvo systems sustain frequently used style software, simplifying the shift from design to execution.

Conclusion

In conclusion, electronic galvo scanners substantially enhance efficiency in laser processing applications with improved precision, boosted operational rate, and versatility throughout different products. As modern technology proceeds to evolve, the adoption of electronic galvo scanners is poised to drive innovations in accuracy design and manufacturing techniques.

Report this page